Sometimes it seems virtually anything can be made into fuel. As though, if we had the right technology, we could throw together old T-shirts, bumper stickers, and pine cones to make a magical elixir to run the millions of cars on North America’s highways.

That’s not an entirely far-fetched scenario. The days of filling up our cars on dead dinosaur goo are likely coming to an end. Instead, we’ll be using fuel made from plants and plant waste. (Don’t hold your breath for the bumper stickers.)

The great white hope in today’s biofuels world is cellulosic ethanol, and the one pre-commercial demonstration plant currently producing it lies in the great white north. It’s run by Iogen Corporation, a Canadian biotech firm that has been around since the 1970s, manufacturing enzyme products for the pulp and paper, textile, and animal-feed industries.

At its cellulose demonstration plant in Ottawa, Canada, Iogen converts wheat, oat, and barley straw into 3 million liters of ethanol per year (about 793,000 gallons). The plant — which began operating in 2004 and has drawn investments from Royal Dutch Shell and Goldman Sachs — was designed to pinpoint any problems with Iogen’s processes before construction begins on a commercial-scale plant.

Grist talked shop with Iogen’s staff recently to find out what goes on at the plant and when and where the company plans to begin producing on a commercial scale — then put together this winsome guide to the world’s favorite fantasy fuel.

What’s the difference between cellulosic ethanol and regular ethanol?

Think of it as the difference between single-grain and multigrain bread. Regular ethanol is made from whole grains like corn or wheat, and this is where cellulosic ethanol has the advantage. It can be made from a much wider range of material — most often from leftover agricultural and forestry waste, such as cereal straws, corn stalks, sawdust, and paper pulp — and the feedstocks can be combined.

Most of the regular ethanol sold in the United States is made from corn, but, according to the U.S. Department of Energy, corn can supply only about 10 percent of the country’s needs. By contrast, there is enough plant biomass for cellulosic ethanol production in the United States to displace 40 percent of the country’s current gasoline consumption.

How does Iogen make cellulosic ethanol?

The wheat, oat, and barley straw is first pretreated. Iogen’s patented enzyme — an active protein made from a fungus — breaks the cellulose down into sugars, which are then fermented and purified into ethanol. The enzymes are nontoxic and biodegradable.

One of the big side benefits is that the plants used to create cellulosic ethanol contain lignin, a compound that is separated out in the process and can then be burned to create energy. Iogen uses the lignin in a combined heat and power plant that generates the energy needed to run the demonstration facility.

Does it cost more than regular gasoline or regular ethanol?

At the moment, yes, but it’s an unfair comparison because cellulosic ethanol hasn’t yet been manufactured on an industrial scale. Tax subsidies to the oil industry distort the true cost of gasoline, but when those distortions are removed, cellulosic ethanol is one of the lowest-cost ways to reduce gasoline usage and is cost-competitive with regular ethanol.

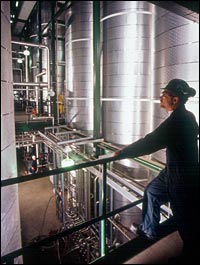

The future looks refine from here.

Photo: Iogen

Since the corn-based ethanol industry has been around for years, it is more cost-effective. This is in part due to the $0.55 per gallon tax exemption it receives, an exemption that, although due to expire in 2007, is likely to be renewed.

A June 2006 U.S. Senate hearing was told that the current cost of producing cellulosic ethanol is $2.25 per gallon, which is not competitive when distribution costs are added. The DOE is asking for more research funding, however, and has a target to cut the cost of production in half by 2012.

What are the environmental benefits? Both regular and cellulosic ethanol are clean-burning fuels with a high percentage of oxygen (35 percent). More oxygen encourages a more complete combustion of the fuel, which in turn reduces emissions.

Using life-cycle analysis, which looks at all of the associated costs and benefits, the DOE’s Argonne National Laboratories determined that using cellulosic ethanol as both a transportation fuel and as a fuel to generate electricity cuts greenhouse-gas emissions by between 80 and 90 percent. Corn-based ethanol cuts emissions by only 20 to 30 percent.

Can my car run on cellulosic ethanol?

Yes. No modifications need to be made because all standard automobiles manufactured in North America must be made to operate on E10 (a blend of 10 percent ethanol and 90 percent gasoline).

Some car companies make what are known as “flex-fuel” cars that can run on a much higher percentage of ethanol-blended gasoline, as high as 95 percent ethanol to five percent gasoline, and there are currently about 4 million flex-fuel vehicles in the United States. In addition, as hydrogen fuel-cell cars emerge onto the North American market, Iogen says that cellulosic ethanol could be used to produce onboard hydrogen.

Does cellulosic ethanol damage a car’s engine?

Just the opposite is true. Vehicles can actually run better because ethanol-blended fuel removes deposits and cleans out fuel lines.

What does Iogen do with the cellulosic ethanol it produces?

As of July 2006, Iogen has been upgrading its research and development plant and, as such, is not currently producing cellulosic ethanol. It has fuel in storage for its own fleet of 13 vehicles, and has supplied cellulosic ethanol to the fleet vehicles of two Canadian government departments in Ottawa (Agriculture Canada and Natural Resources Canada). Iogen also supplied the fuel for the leaders’ cars during the G8 summit in Scotland in July 2005 and at the Convention of the Parties (COP11) in Montreal in December 2005.

When can we expect to see the first commercial plant built? Iogen plans to license its technology and expects that its first commercial plant will have the capacity to produce 20 million gallons of cellulosic ethanol per year using corn stalks and cereal straws as the feedstock. The company has its eye on three potential sites — north central Saskatchewan, east central Alberta, and southeast Idaho — but no decision has yet been made.

So what’s the holdup?

Because a cellulosic ethanol bio-refinery involves new and unproven technology, normal project financing is not available without a third-party guarantee, Iogen says. Risk sharing, in the form of government grants and loan guarantees, will be critical to commercialization.

Iogen says that government support is the only missing link; the company says it needs some fairly hefty federal support to share the risk of its first plant. The U.S. government has legislation to support production of cellulosic ethanol; Canada doesn’t, but the company believes it could move quickly if the government decided to step in.