Images of a clean-energy future tend to feature wind turbines and solar panels, iconic symbols of the struggle to halt global warming. But the United States is pursuing a much wider range of solutions to drive down greenhouse gas emissions. Soon, a direct air capture facility, or a carbon capture and storage project, or a clean hydrogen hub could be proposed in a town near you. Maybe one already has. Two recent laws — last year’s bipartisan infrastructure legislation and this year’s Inflation Reduction Act — offer developers billions of dollars to build these kinds of projects.

Experts say these technologies are needed to tackle climate change. They can help cut carbon from hard-to-decarbonize parts of the economy that cannot simply switch over to renewable electricity. But there are very few large-scale examples operating today. To help people visualize what all this new infrastructure could look like, Third Way, a center-left D.C. think tank, commissioned the design studio Gensler to illustrate hypothetical projects, showing how they could be integrated into communities and local economies.

“Many communities in the U.S., particularly those historically impacted by environmental injustice and unequal distribution of economic benefits, have valid concerns” about these technologies, said Rudra Kapila, a senior policy advisor at Third Way who led the project. In creating these images, she said she hoped to “facilitate constructive conversations on how communities can safely live and work in a changing energy landscape.”

Of course, a series of images can only go so far in answering the questions and concerns that people may have about living near these projects. But the scenes may help sharpen those questions by giving shape to the scale of the infrastructure, its purpose, where it might go, and its potential risks and benefits.

The first three images depict direct air capture projects of different sizes and in different settings. Direct air capture, or DAC, facilities filter carbon dioxide out of the atmosphere. Their purpose is twofold: By removing carbon from the air, they can balance out emissions from activities like farming and flying that might be hard to eliminate at the source. DAC could also eventually help reverse global warming if we build enough machines to pull more carbon out of the atmosphere than we’re putting in.

“I think the specific challenges of a direct air capture plant is that they don’t really exist, outside of a couple demonstrations in Europe,” said Shuchi Talati, a senior visiting scholar at the nonprofit Carbon180, which advocates for policies to support DAC and other carbon removal methods but was not involved in creating the images. “And so the biggest challenge is helping people visualize and understand something that they’ve never seen before and have never really thought about.”

In this first image, small, modular DAC plants — similar to a model currently operating in Switzerland — are installed on the roofs of factories in an industrial part of a suburban town. Kapila warned that the fans on the equipment are loud and should not be sited on or near a school, for example. Here, the machines are powered by electricity from rooftop solar farms and a wind farm in the background.

This first image also raises a key question for anyone appraising a DAC project: What will happen to the captured CO2? In Kapila’s narrative of this scene, the “DACME” construction company in the background uses the CO2 as a key ingredient in the concrete it sells. This isn’t far-fetched — there are already a few companies working on embedding CO2 in concrete. The trucks in the foreground suggest a more controversial idea — selling the CO2 to soda companies for carbonation. Kapila said she included the concept because of a reported shortage of CO2 in the beverage industry. But CO2 used for beverage carbonation quickly gets emitted again, meaning a lot of energy would be spent to capture CO2 for no climate benefit.

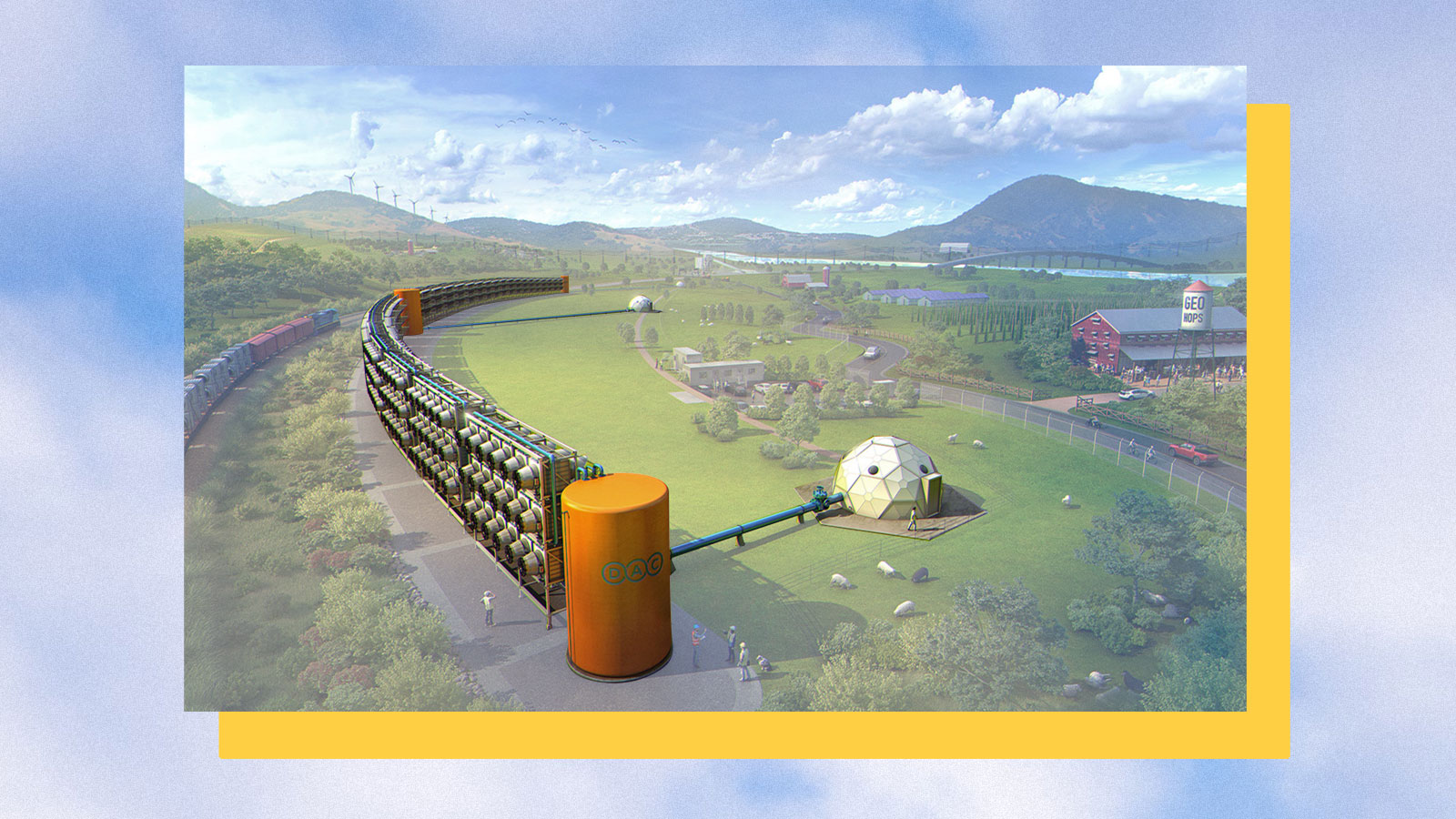

The second image features a project that’s very similar to another existing DAC plant in Iceland, the largest currently operating in the world. Like that facility, the one shown here runs on geothermal energy, a renewable resource that draws on heat beneath the earth’s surface, from a power plant across the river. The scene also shows the carbon dioxide being delivered directly to underground sequestration sites for permanent storage — those geodesic domes are modeled off real CO2 sequestration facilities in Iceland. (You may notice there’s more going on in this scene — Kapila incorporated many ideas about how these technologies could be integrated into local economies into each image, which are mapped out in a series of additional renderings on the project website.)

The clusters of mega-DAC projects depicted in this third image, all powered by a nuclear plant, would pull hundreds of thousands of tons of CO2 out of the air each year. A pipeline on the right side, which Kapila said is meant to be a repurposed oil pipeline, carries the CO2 to underground storage sites. “There have been provisions, both in the Inflation Reduction Act and in the infrastructure bill, specifically for making use of existing infrastructure,” she said.

Kapila said this hub of DAC plants could be sited in the desert of Texas or New Mexico, currently a major oil-producing region. While no facility of this size exists today, the oil and gas company Occidental is currently building one in West Texas. But unlike the plant depicted here, that facility is planned to run at least in part on natural gas power. And unlike in Kapila’s illustration, some of the CO2 the Occidental plant collects is expected to be piped out to low-producing oil wells, where it will be injected underground in order to dislodge the last drops of oil.

Many climate and environmental justice advocates have campaigned against the use of direct air capture, in part because of its potential to prop up the use of fossil fuels. Kapila said she sought to show people that we can design these systems to be independent of fossil fuels, or in a way that greatly diminishes their role in the economy.

Talati, who previously worked at the Department of Energy’s Office of Fossil Energy and Carbon Management, said it’s essential to start to build a common understanding of what “good” DAC projects look like. “We need to build a lot more knowledge, whether that’s in communities where DAC might be built, across civil society, and across policy makers,” she said.

At the same time, Talati warned that the goal of these conversations should not be to drive public acceptance of these projects. “I think that can be a dangerous way to talk about it, because that means that you are trying to convince people of something without taking the time to build knowledge and understanding,” she said. “When we think about public engagement, I think we want to make sure that we don’t have a preordained outcome in mind.”

The last two scenes that Third Way created venture into different territory, looking at how to lower emissions at existing heavy industrial sites.

The first reimagines a Gulf Coast port as a hub for the production of clean hydrogen. Hydrogen is a fuel that has the potential to sub in for fossil fuels in a number of applications, and it doesn’t release any greenhouse gases when it’s burned.

In this scene, an offshore oil platform has been repurposed for hydrogen production, which can then be used to fuel the ships in the port. Today, the vast majority of hydrogen is produced from natural gas in a process that emits carbon dioxide. But here, offshore wind powers the process, using electricity to split water molecules into hydrogen and oxygen. Experts often call this method “green hydrogen,” and while it’s only done at a few small facilities today, it’s set to grow rapidly. The bipartisan infrastructure law gave the Department of Energy $8 billion to spend on clean hydrogen hubs, and a new tax credit created by the Inflation Reduction Act will pay producers up to $3 for each kilogram of clean hydrogen they make.

Onshore in this scene you’ll find more DAC machines capturing CO2 from the atmosphere. There is also a blending facility, where the hydrogen could be blended with the captured CO2 to create what’s called a synthetic fuel. Blending hydrogen makes it easier to store, transport, and use with existing technologies. But using captured CO2 to make fuels will ultimately release it back into the atmosphere.

The final image in the series portrays a steel plant, modeled on an existing plant in Pennsylvania, outfitted with a technology called point source carbon capture.

Instead of sucking carbon dioxide out of the air, as DAC machines do, similar equipment is installed on the flue of the steel plant, capturing carbon before it enters the atmosphere. A defunct coal mine is also visible in the background, symbolizing the potential to store captured CO2 in unmined coal seams.

The U.S. iron and steel industry sent about 66.3 million metric tons of carbon dioxide into the atmosphere in 2021, or about as much as 14 million gas-powered cars emit over a year. Steel is a notorious climate challenge, because its use in buildings, vehicles, and appliances make it so integral to modern life, but we don’t yet have many options for making it cleaner. Steelmaking requires massive amounts of energy to produce heat, and it also uses coal in the chemical reaction that turns iron into steel. While some companies are making progress with alternative chemistries, carbon capture is considered one of the best bets for slashing emissions from the sector in the near term.

Kapil acknowledged the challenges of drumming up public interest in carbon capture technology. “Point source carbon capture, it’s as glamorous as urban plumbing,” she quipped. “But the thing is, we need these systems. To say that we can function without steel would be, you know, we can’t.”